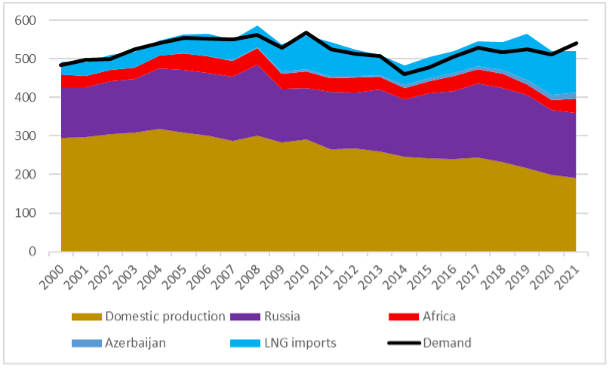

While there is a great deal of enthusiasm and even hype for renewable energy sources such as solar and wind, the fact remains that natural gas contributes a large portion of our energy needs.

In fact, natural gas power plants generate around 23% of the world's electricity, primarily in the United States, Russia, Saudi Arabia, and Iran.

As shown in the International Energy Agency (IEA) chart above, this capacity is second only to coal.

But unlike coal, the gas fraction of the generation mix is expected to grow for years to come. This is primarily because natural gas power plants are cheap and quick to build. They also demonstrate very high thermodynamic efficiencies compared to other power plants.

A gas-fired power station is also more flexible and needs less time to start and stop than its coal-fired equivalent. It follows that natural gas projects partner well with variable renewable energy sources such as solar and wind.

What’s more, Shell believes global demand for gas will increase by 40% from 2014 to 2030.

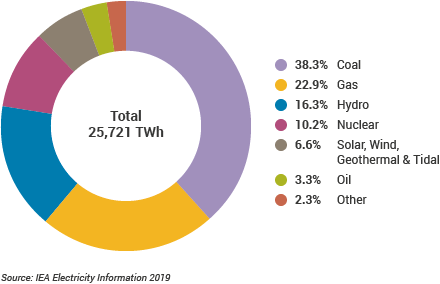

This is mirrored by Statista’s projections of natural gas power generation capacity worldwide through to 2050:

Source: Statista - Installed natural gas power generation capacity worldwide from 2018 to 2050 (in gigawatts)

This means that natural gas's climate change impact will continue to grow, ideally at the expense of coal. Coal will lose out not only from a cost perspective but also from the fact that natural gas combustion produces just 50% of the carbon dioxide (CO2) and just 10% of the air pollutants of coal.

(Incidentally, this is why air quality tends to improve when switching to natural gas plants from coal plants, although not to the same degree as with nuclear, wind or solar.)

All these factors added together mean natural gas will remain a part of the global power mix for decades to come, even as renewables usage continues to grow.

Before delving into the costs associated with natural gas plants, a brief discussion of the technology is useful.

A Simple Look At Natural Gas Turbine Technology

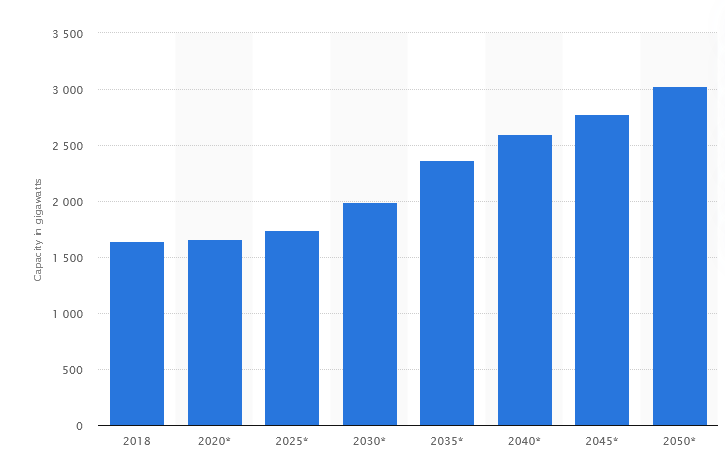

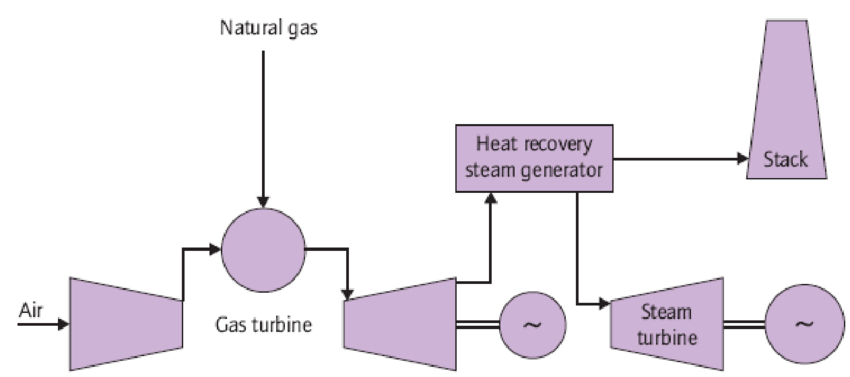

Natural gas turbine plants operate in a straightforward and well-understood way. There are both simple-cycle gas plants and combined cycle gas plants.

Simple-cycle plants burn natural gas combined with air within a gas turbine, which in turn spins a generator and generates electricity.

Source: Researchgate - Schematic diagram of a simple-cycle, single-shaft gas turbine.

Simple-cycle plants make no use of the heat generated by the gas combustion and are therefore less efficient than a combined cycle gas turbine (CCGT). Only 33% of the natural gas energy is delivered as electricity, although they are quicker to turn on and off to meet dynamic load needs.

There is considerably less wastage of generated heat with a combined cycle gas turbine (CCGT) plant. A CCGT is a simple cycle plant combined with an external combustion engine called a heat recovery steam generator (HRSG).

Source: Researchgate - Possible process flow diagram of a Natural Gas-fired Combined Cycle power plant (Henderson 2007)

The HRSG is a heat exchanger which uses the hot exhaust gases from the simple-cycle plant to boil pre-heated water into steam. This steam in turn spins another turbine and generates yet more electricity.

This is how the thermal efficiency of a combined cycle gas plant can reach 60% while generating only 33% of the waste heat of a simple-cycle plant.

As you might expect, a combined cycle plant costs more due to its added complexity and materials.

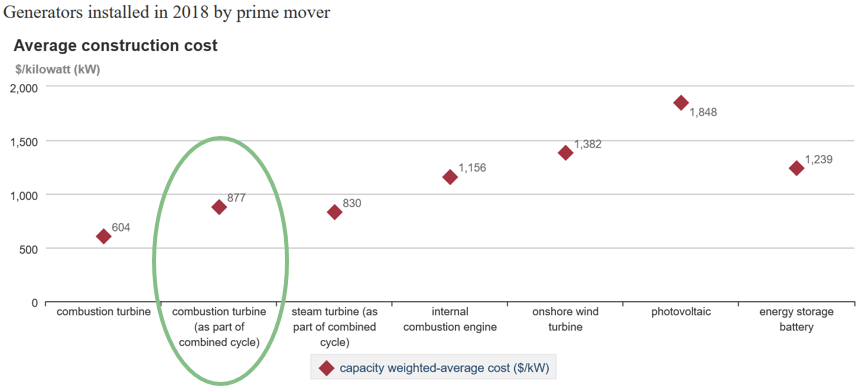

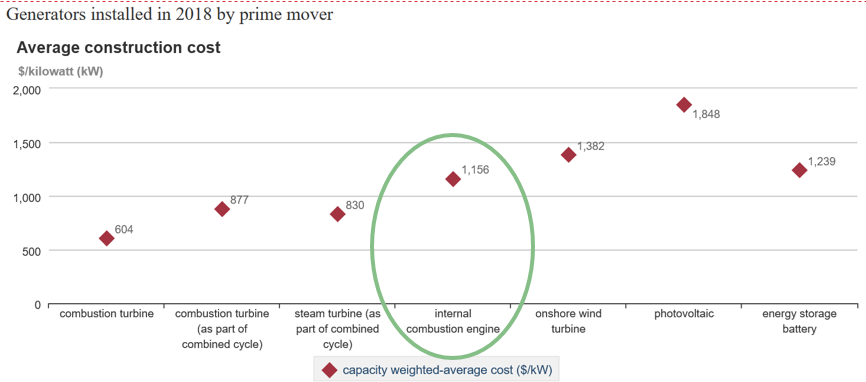

The Energy Information Administration (EIA) reports that combined cycle installations cost $877/kW against $604/kW for a simple cycle installation.

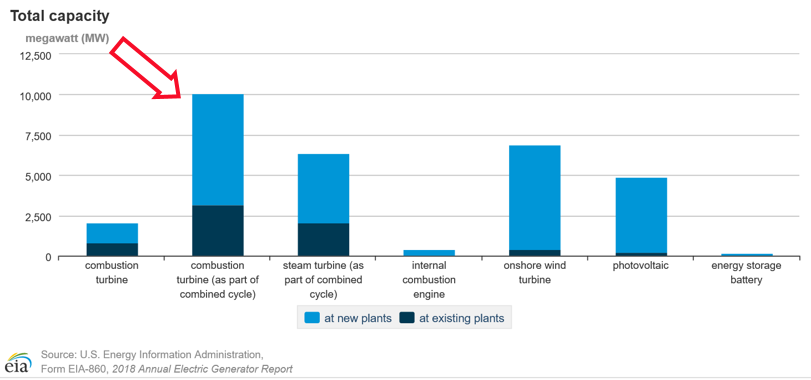

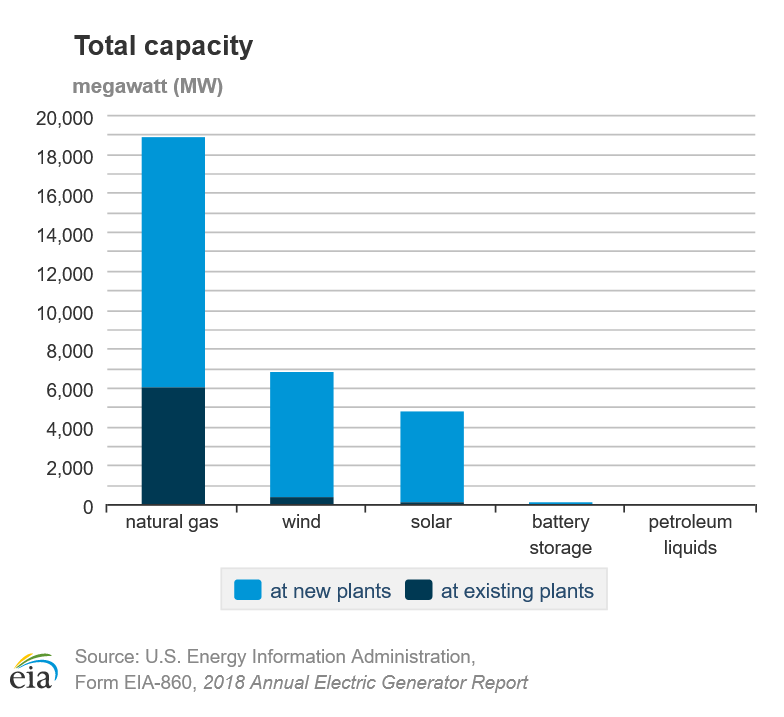

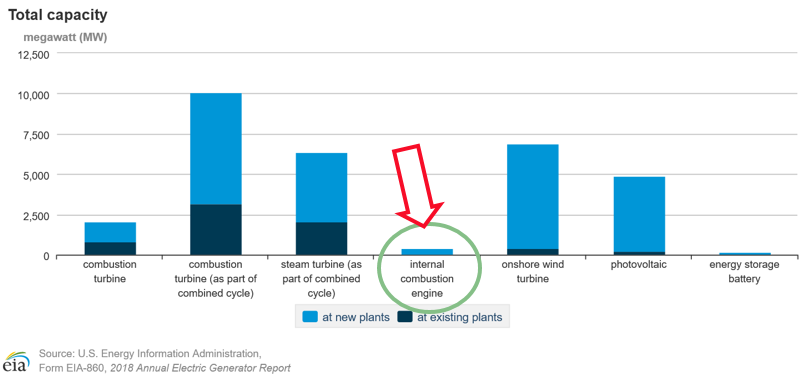

However, the higher cost is not a deterrent due to the CCGT’s much higher efficiency. The EIA shows the installed and new capacity of combined cycle generation vastly exceeds the competition:

According to the EIA data, only onshore wind turbines come close in total capacity with 7,300 MW compared to 10,000 MW for combined cycle gas turbines.

So how much do natural gas plants cost in comparison to other energy sources?

There are two considerations:

- initial capital expenditure costs for construction and commissioning, and also

- ongoing operating costs to keep the plants generating electricity and revenue for their operators

Let’s start with the first of these expenses.

Natural Gas Turbine Start-Up Costs

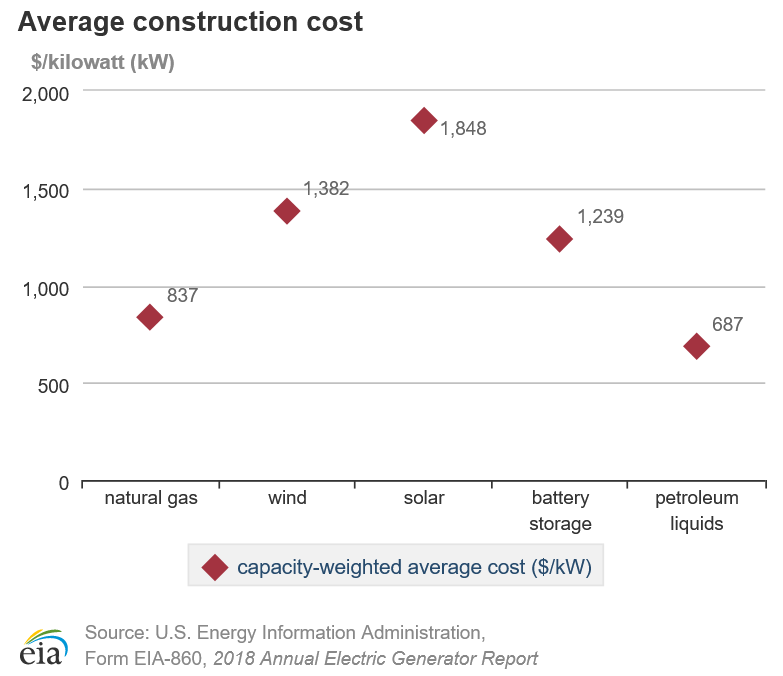

The EIA also created this plot of US construction costs by major energy source:

Natural gas construction is still cheaper than wind, solar, or batteries although of course, this does not include fuel costs and other operations and maintenance (O&M) cost for a natural gas plant.

This lower initial cost is no doubt the reason why US total capacity (both existing and new) still dwarfs the contributions from the other highlighted sources:

In combination with the Shell and Statista growth projections at the beginning of this article, it’s clear that natural gas plants will remain a large and growing part of the energy mix for the foreseeable future.

Now for the ongoing costs of running these power plants.

How Natural Gas Turbine Operations & Maintenance Costs Stack Up

All energy generation businesses incur operation and maintenance (O&M) expenses to function.

These fixed and variable ongoing costs include day-to-day preventative and corrective maintenance, labour, asset and site management, health and safety, and related expenses.

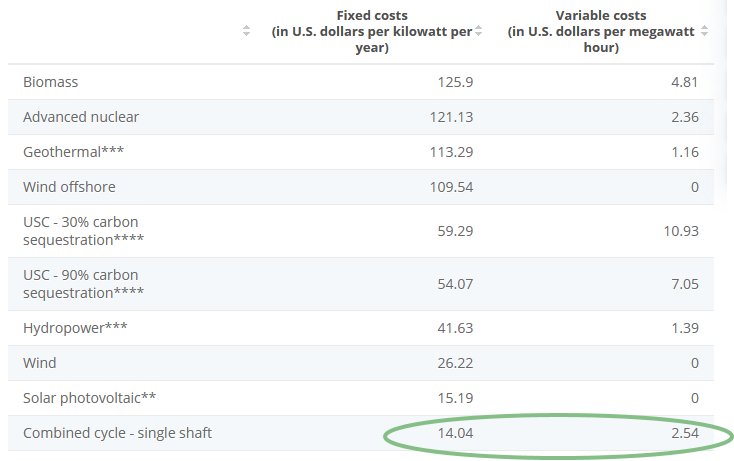

O&M costs vary widely between different power generation methods, as this table from Statista shows:

Source: Statista – Power plant operation and maintenance costs in the U.S. in 2019, by technology

Combined cycle gas turbines compare very favorably to all competing sources except solar, where they are close to parity.

Key O&M costs for combined cycle gas turbines include the lubrication system acting as preventative maintenance for the multiple moving parts, especially when frequent starts and stops are needed to fill gaps left by solar and wind generation technologies.

Power Technology claims combined-cycle gas turbine (CCGT) technology can generate electricity at an average O&M cost of $25/kW, while the cogeneration achieved by these plants with combined heat and power (CHP) pushes efficiency to more than 80% for a modest O&M bump.

And speaking of solar, cleaning and removing debris from panels while monitoring inverter units and AC subsystems are the primary maintenance tasks. Power Technology reports that O&M costs here are also $25/kW.

Meanwhile, O&M expenses for onshore wind power sites now rival coal at $46/kW.

But What About Gas Engine Technology?

Often overlooked due to their smaller market share, gas power plants are also a viable means of exploiting the clean energy aspects of natural gas combustion.

Therefore gas turbine technology total costs, on both a capex and opex basis, remain competitive with solar, wind, coal and also nuclear, not just today but also into the foreseeable future.

Gas power plants powered by gas engine technology are simply large (5 – 20 MW) internal combustion engines that use natural gas as their main fuel. Many are 'lean-burning', meaning that the gas is mixed with air before reaching the inlet valves, fed into a small pre-chamber where the gas mixture is high compared to the main cylinder, and then ignited by a spark plug which in turn ignites the gas in the cylinder. This ensures fast combustion and lower pollution levels.

Gas engine technology typically burns fuel with an electrical efficiency that can rise as high as 50% in simple cycle and 54% in combined cycle mode.

They also enjoy the flexibility common to internal combustion engines we see in our everyday lives: they can quickly start, accelerate and stop according to specific needs, and require only a negligible amount of cooling water relative to their power output.

When combined with the clean-burning aspects of natural gas as a fuel, these features ensure they have only low environmental impact.

Common applications include cogeneration with wind and solar power as well as CHP (Combined Heat and Power) across a variety of industries including automotive and steel as well as mobile and emergency power.

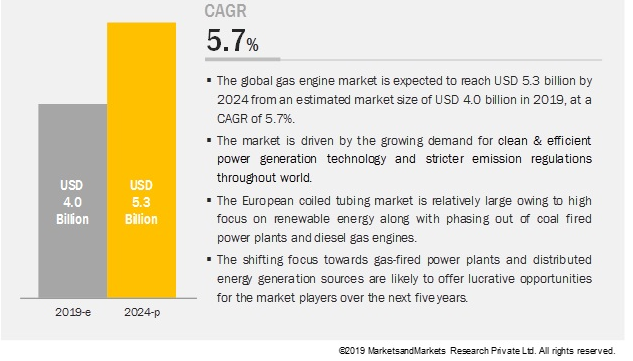

Markets and Markets reports that natural gas engines are expected to grow at a 5.7% CAGR (compound annual growth rate) through to 2024.

Markets and Markets also notes that the natural gas segment led the gas engine market in 2018. Baseload power generation and CHP were the lead applications, with utilities the primary users. Moreover, cogeneration to produce power alongside energy for space heating and water heating is expected to grow the fastest.

Cost-wise, the EIA reports that gas engines are slightly more expensive to construct than turbines but cheaper than wind, PV, and battery storage.

Gas Engine Plant Advantages

While less well known, gas engine technology plants do offer several advantages over gas turbines.

Internal combustion engine plants can reach full load in 2-10 minutes as opposed to over 30 minutes for turbines.

They can also be built in a modular fashion with multiple generating units working together to generate power. If one breaks down, the others can continue to function and even raise their output to maintain continuity. Gas Engine Plants can operate at part-loads with high efficiency. They also have faster ramp rates (the rate at which they can increase or decrease their outputs) than turbines.

Combustion engines are also less sensitive to temperature and humidity when operating, making them more suitable for harsh climates.

Additionally, specifically-designed gas engines can operate on other fuels if natural gas is unavailable, such as flue gases where incomplete combustion took place, LNG, PNG, and various biogases, light fuel oil, heavy fuel oil, crude oil or liquid biofuel. Such multi-fuel engines can switch fuels while maintaining their output and efficiency, unlike gas turbines which have reduced availability and output when running on fuel oils.

This makes gas engine power plants a viable alternative to turbines while still taking full advantage of the benefits of using natural gas to partner with variable solar and wind power generation.

Which gas power option is right for you?

How ADC Projects Can Help

At ADC Projects, we sell expertise in the energy market to commerce and industry, including both big and small hybrid solutions. We provide Project Development, Project Management Operations and Maintenance, Engineering and consulting services to develop and install a variety of power projects.

To learn more about becoming less dependent on utility power, saving time & money and gaining a real advantage over your competition, please contact us today.