It’s no secret that renewable energy sources such as solar and wind are intermittent and not as dispatchable as energy providers and end users would like. (“Dispatchable” refers to the energy source’s ability to provide power on demand by turning it on or off as needed.) However, renewable-generated energy can be made dispatchable with energy storage sized and matched to the need of the grid operator. Most people think of batteries (lithium-ion batteries in particular) when they think of storage. However, batteries are far from the only way to keep energy on tap until it’s needed.

Alternative storage mediums include sand or ceramic pellets, flywheels, and redox flow batteries. All three solutions have been deployed in existing energy projects and will likely play more significant roles as each technology continues to mature. Let’s cover each solution’s strengths and weaknesses.

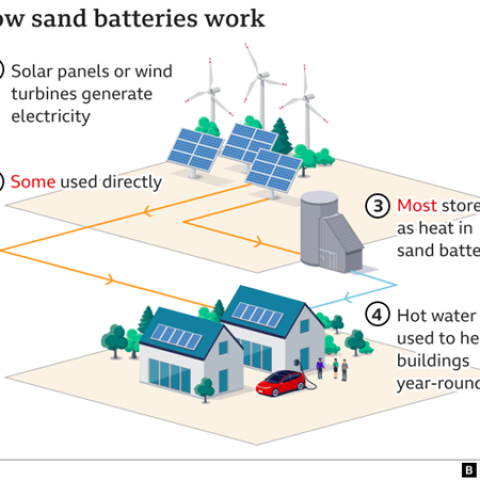

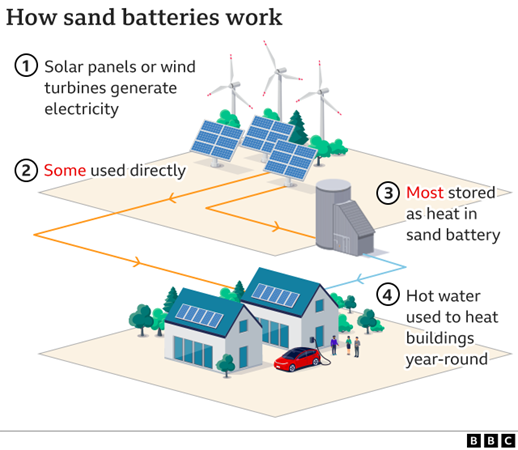

Sand or Ceramic Pellets: Sometimes the simplest solution is the best. As anyone who’s visited a hot summer beach can attest, heat can be easily transferred into sand grains -- or their ceramic equivalent. In a suitable receptacle, this heat energy can be stored for as long as 20 hours at temperatures as high as 1000℃/1850℉.

When released, the heat drives a turbine which in turn creates electricity without combustion or emissions. Alternatively, the heat can also be used for food and drink, textiles or pharmaceuticals processes as well as general building heating.

Source: BBC: Climate change: 'Sand battery' could solve green energy's big problem

This technology is already proving useful when cost is an important consideration.

As deployed in remote villages in Mozambique, sand/pellet “batteries” have a long life cycle of 20 years or more. Each thermal battery provides 200kWe and has all but eliminated wood-fired cooking, generators and their associated fuel costs while providing 24/7 low-carbon power and heat to each local village. The technology is also cheap at just $50/MWh.

A similar installation in South Australia (200kWe power, 1.8MWh energy in a single battery) generates an additional $100,000 revenue per year for the solar farm to which it’s attached. This ‘sand battery’ eliminates curtailment from the solar farm and has created a new revenue stream for the operator while saving costs due to load shifting.

The drawbacks of sand or pellet storage include short storage times and limited efficiency.

However, a larger commercial sand battery is now operating in Finland. This installation can store 8MWh of energy to produce 100kW from sand heated to around 500-600 degrees Celsius (932-1112 °F). What’s more, the company claims the system is up to 99% efficient when used for process heat. The installer also claims this system is capable of storing heat for months while being fully automated.

It remains to be seen if these claims are valid, but the main attractions of sand or ceramic pellet “batteries” are indisputable. Their confirmed low cost and simplicity and lack of complex chemistries or exotic materials are key advantages. The technology is proven and easily deployed to most any solar or wind power location.

Flywheels: This is a kinetic energy storage solution where electrical energy generated by renewables is transformed into kinetic energy that spins the wheel.

The process is fast and responds quickly to changing demand. For example, spinning flywheels operating at up to 45,000 rpm can charge or discharge in seconds. This makes them excellent choices to balance sudden supply or demand changes and frequency regulation applications.

Most flywheels float magnetically in a vacuum and – due to minimal friction and wear – have low maintenance requirements while maintaining 85% round trip efficiency.

Even better, flywheels can operate across a wide variety of temperatures with a lifetime of 20 years or more.

They can also be cycled an unlimited number of times each day and they are also highly modular. Their relatively low cost and predictable operations costs offer additional advantages.

Source: Stornetic - A typical flywheel energy storage example

There is a downside, however. Flywheels cannot provide baseload power and their energy supply is relatively small.

For example, one major installation in Ontario, Canada can provide 2MW of power from 10 flywheels for only 15 minutes.

Other solutions include flywheels offering 8kW of power and 32kWh of energy in a single two-ton steel rotor which can be scaled up across multiple wheels.

Still other installations in Germany and France feature capacities ranging as high as 560kW and 95kWh capacity from 22 flywheel machines. These installations help avoid power mismatch penalties charged to operators while smoothing solar and wind power source outputs to the grid.

This means that flywheels offer useful low-cost, rapid-response energy storage with long lifetimes, but only for specialized short-term applications.

Vanadium Redox Flow Batteries: These are chemical batteries, but they operate quite differently from most other battery types.

In redox flow batteries, vanadium-based electrolytes are stored in separated storage tanks as liquids. The liquids are pumped to flow through a stack of power cells and a membrane.

Source: Wikipedia - How a vanadium redox flow battery is structured

The membrane is where a reversible reduction-oxidation (“redox”) electro-chemical reaction charges or discharges the battery. The electrolyte is water and either sulphuric or hydrochloric acid with vanadium at different oxidation states on each side.

These flow batteries can be charged over 35,000 times over a 20 year lifespan and can be discharged to 0% charge without ill effect. There is no fire risk and the components can be recycled or reused.

Another key advantage is flexibility. Each battery’s energy capacity can be increased simply by adding more or larger electrolyte tanks. Power can be increased by adding power cells at the membrane separating one side from the other.

On the other hand, flow batteries have relatively poor energy-to-volume ratios and round trip efficiencies compared to more conventional batteries. They are also heavy and the vanadium oxides are toxic. This makes them suitable only for large-scale projects where space is not a major factor.

Significant installations operating today include a project in Japan that generates 15MW of power from 60MWh of storage. Another project in Germany produces 2MW of power from 20MWh of storage. These capacities are comparable to many lithium-ion battery solutions.

Smaller projects include a hybrid solar and flow battery solution in South Africa where the battery provides 1MW of power from 4MWh of storage to the Vametco Mine (a vanadium-producing operation itself, ironically). The battery helps cut energy costs while allowing time of use arbitrage, peak demand reduction, and improved power quality just as a more well-known lithium ion installation.

In summary, vanadium flow batteries offer long lifespans and are much more resilient to a variety of climate conditions than lithium ion batteries. They are also easy to expand from both a power and energy standpoint. Their main drawback is a low energy density and a considerable space requirement for the tanks holding the aqueous electrolytes.

More Alternative Storage Solutions Are On The Way

Sand and ceramic pellets, flywheels and vanadium redox flow battery solutions are all in use today and will likely see increased deployments as more data is gathered to prove their relative advantages as compared to lithium ion batteries.

However, there are competitors waiting in the wings which could see commercial deployment in the near future. These include graphene supercapacitors, liquid metal batteries, and iron-air batteries.

Here’s a quick look at each of these technologies:

Graphene Supercapacitors: Supercapacitors consist of two metal plates coated with a porous material known as activated carbon. The plates are separated by an insulator. During charging, electrons accumulate rapidly on one conductor and depart from the other. The process reverses during discharge.

The main advantage of the technology is the speed of charge and discharge, while the main drawback is is the cost.

Meanwhile, graphene is a novel structure of thin, pure carbon which has a number of novel properties useful for energy storage purposes. It promises to reduce the cost of existing supercapacitors while increasing their energy storage capabilities.

In fact, a graphene supercapacitor should be able to store nearly as much energy as a lithium-ion battery while charging in mere seconds and boasting a lifetime of literally tens of thousands of charging cycles.

This would allow the technology to replace batteries and offer a wider range of use cases beyond existing supercapacitor applications such as burst power, regenerative braking systems, and backup power initiations.

Liquid Metal Batteries: High temperature redox batteries active at around 500ºC are being developed today. The anode is a liquid calcium alloy, the cathode is made of antimony and the electrolyte is molten salt.

Once heated to operating temperature, the metal layers float on top of each other based on density differences. This means they have no moving parts, are not subject to the fragmentation or fracture stresses of solid batteries, and can respond to grid signals in milliseconds.

The all-liquid cells are cheap to make and last 20 or more years over thousands of charge and discharge cycles.

What’s more, the design is modular and can be easily expanded with larger storage tanks and more metals. The materials are abundant and relatively simple to source.

The technology has already passed safety certification tests as it does not produce or emit any gases and there are no thermal runaway issues.

Iron-Air Batteries: Something called “reversible rusting” acts as the operating principle behind this technology.

As it discharges, the battery absorbs oxygen from the air and oxidizes iron metal to rust. This releases electrons to power the grid or other load. The battery is then recharged with an electrical current which converts the rust back to iron while releasing oxygen.

This is a heavy battery which offers a cost-effective, non-toxic and safe solution. It’s also easily scaled to meet expanding grid needs. It also offers long discharge times of more than 100 hours.

There is no risk of thermal runaway and the cost is just a fraction of comparable lithium-ion batteries.

However, the energy density is low: these batteries currently generate 1MW per acre of land. This means they are only suitable for locations where space is not at a premium.

Iron-air batteries are not yet being deployed to make renewable energy projects more dispatchable.

However, this technology – plus graphene supercapacitors and liquid metal batteries – is promising enough that they’re all worth watching in the near future.

So where do we come in?

How ADC Projects Can Help

At ADC Projects, we offer our energy market expertise to commerce and industry. That includes renewables generation as well as the energy storage solutions needed to make them more dispatchable, viable and profitable.

Our breadth of experience allows us to provide both big and small solutions at all stages of implementation including Project Development, Project Management Operations and Maintenance, Engineering and consulting services.

We have developed and installed a variety of renewable power projects and energy storage projects as well as natural gas-themed installations including gas engines.

With an unfolding energy crisis facing the world today, it’s now more important than ever to get the most out of any energy project. Please contact us today for more information on how we can help.

Andries van Tonder

Andries[at]adcprojects.com

Henry Venter

Henry[at]adcprojects.com

Sources

- https://247solar.com/sustainable-solar-solutions-products/heatstore/

- https://www.bbc.com/news/science-environment-61996520

- https://247solar.com/rural-electrification-case-study-affordable-247-clean-power-heat/

- https://247solar.com/24-7-pv-farms-round-the-clock-power-from-solar-panels/

- https://newatlas.com/energy/sand-battery-polar-night/

- https://www.stornetic.com/our-technology/enwheel

- https://en.wikipedia.org/wiki/Flywheel_energy_storage

- https://amberkinetics.com/product/

- https://en.wikipedia.org/wiki/Minto_Flywheel_Facility

- https://amberkinetics.com/installation/developing-solutions-through-shared-expertise/

- https://www.bushveldenergy.com/technology/

- https://en.wikipedia.org/wiki/Vanadium_redox_battery

- https://www.bushveldenergy.com/company/projects/

- https://www.graphene-info.com/graphene-supercapacitors

- https:/ambri.com/benefits/

- https://www.asme.org/topics-resources/content/liquid-metal-batteries-may-revolutionize-energy

- https://www.prnewswire.com/news-releases/ambri-batteries-achieve-certification-for-its-liquid-metal-battery-cells-301590611.html

- https://formenergy.com/technology/battery-technology/